Prerequisites

Atmospheric distribution system (see Life Support I)

Adequate gas supply for container storage

Objectives

Automatically recharge EVA suits (battery, gases, exhaust removal)

Deliver gases to equipment using portable canisters instead of permanent pipes

Constraints

Portable canisters must survive fire conditions up to 300°C (fuel mixtures excluded due to combustion risk)

Canister charging stations must be able to safely support both standard canisters and smart canisters

Need a way to reintegrate unused gases back into the atmospheric recovery unit

Materials and Components

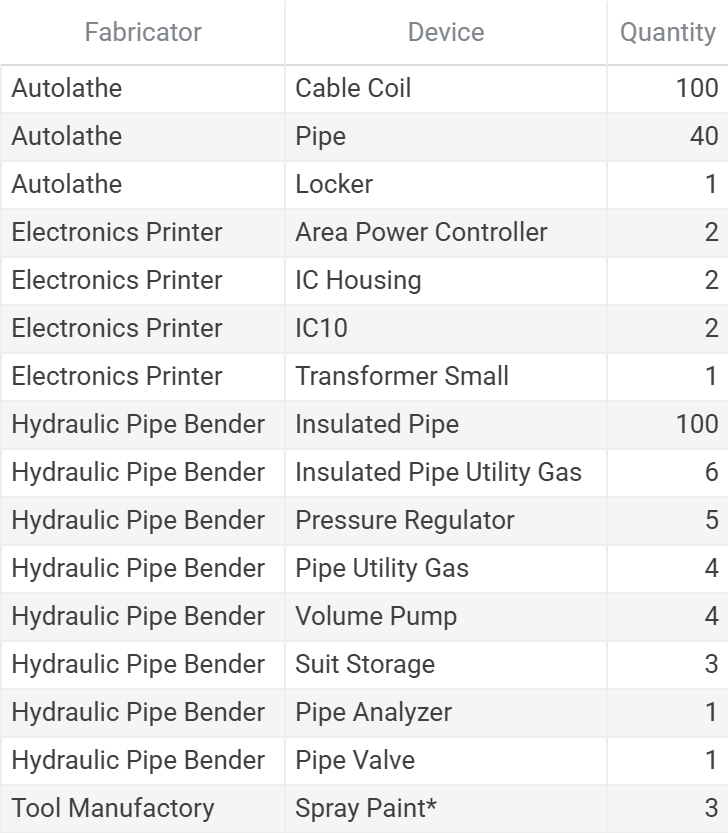

Fabricated Components

* Spray Paint Colors: 1 Black, 1 White, 1 Gray

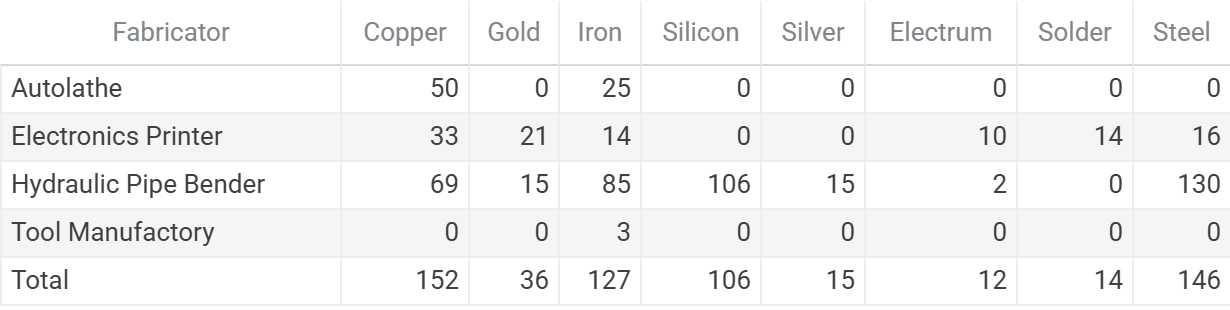

Total Ingots

Raw Ores

This chart format is standardized across the series. See the full legend in Atmospheric Recovery on the Moon, Appendix A11. Bill of Materials.

Ores:

- Coal - 2 stacks

- Copper - 4 stacks

- Gold - 4 stacks

- Iron - 12 stacks

- Lead - 1 stack

- Silicon - 3 stacks

- Silver - 3 stacks

Ingots:

- Copper →

- Copper: 1/1/2/0

- Gold →

- Gold: 0/1/1/0

- Iron →

- Iron: 1/1/2/1

- Silicon →

- Silicon: 0/0/3/0

- Silver →

- Silver: 0/0/1/0

- Electrum →

- Gold: 0/1/1/0

- Silver: 0/1/1/0

- Solder →

- Iron: 0/1/0/0

- Lead: 0/1/0/0

- Steel →

- Coal: 0/1/1/0

- Iron: 0/3/3/0Power Infrastructure

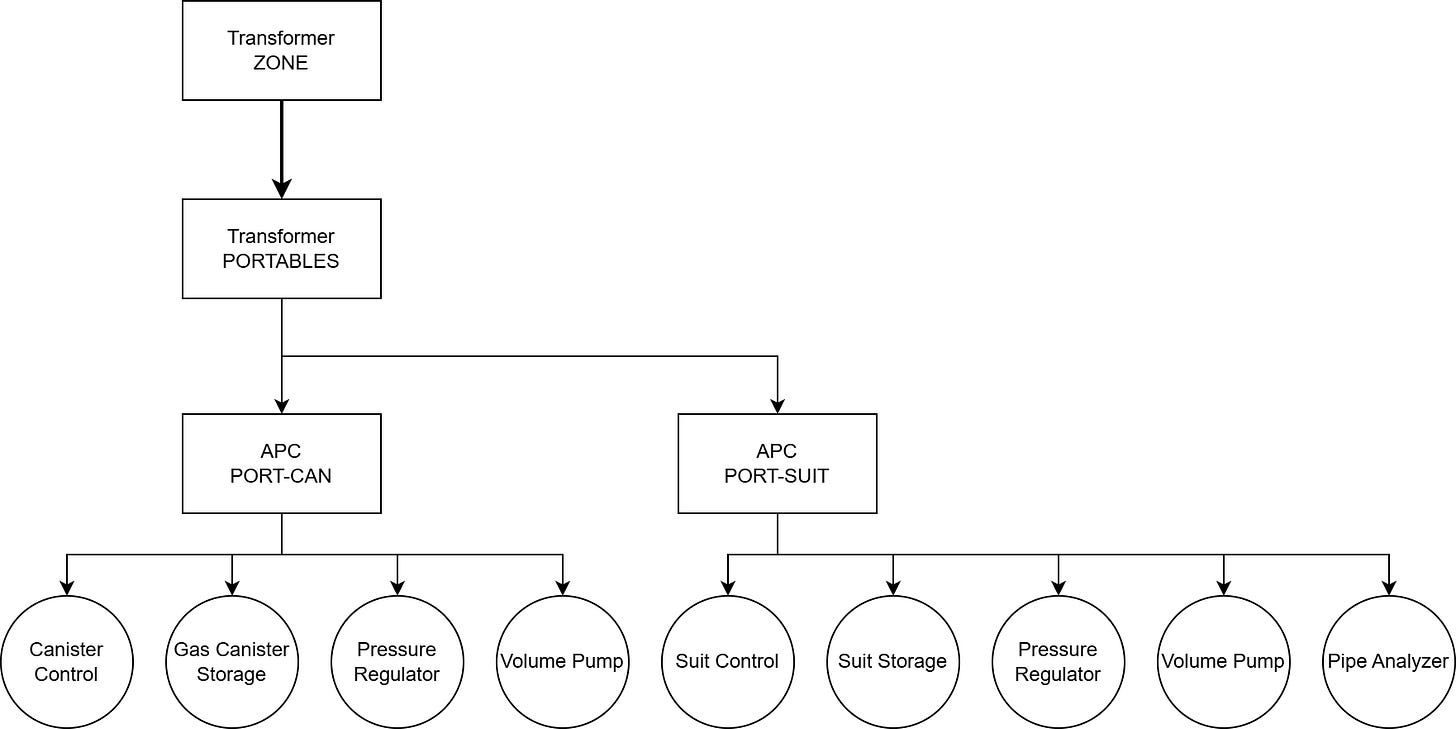

Portables systems operate on a dedicated power hierarchy within the zone network, enabling independent fault isolation and priority management.

The portables transformer (2667 W) feeds two isolated APCs:

PORT-SUIT — Suit storage operations (battery charging, gas refills, exhaust evacuation)

PORT-CAN — Canister fill and evacuation

Emergency Power

The PORT-CAN APC accepts an optional backup battery, enabling emergency canister fills during power outages or transformer failures. This ensures critical gas delivery capability remains available when primary power is unavailable.

Power Budget

Operations complete in under one minute each, with total active with time budgeted at 60 seconds per lunar day (218 kJ). Controller idle power (100 W continuous) represents the primary ongoing draw.

Parallel Construction Tracks

This build consists of two independent construction tracks that can be completed in any order based on priorities and available construction time.

Track Overview:

Suit Storage - Automated system for recharging suit batteries, refilling breathing (O2) and propellant (N2) gases, and evacuating exhaust tanks. Processes up to 6 suits sequentially to minimize power load

Canister Fill Station - Gas filling and evacuating infrastructure for portable canisters. Supports configurable gas types (O2, N2, CO2) with automatic canister detection and exhaust recovery to atmospheric processing.

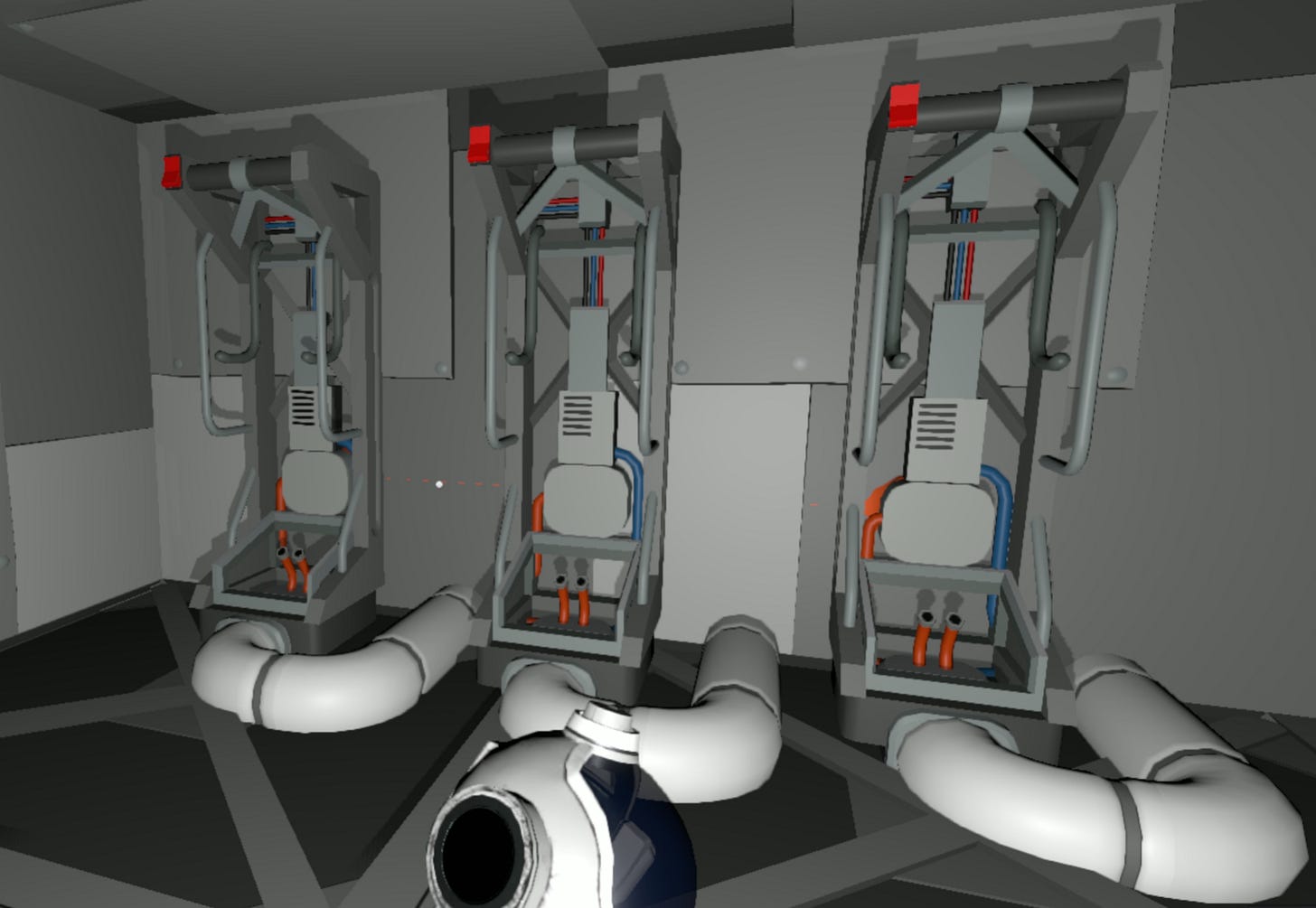

Track 1: Suit Storage

This build provides infrastructure to support three suit storages. A single controller can manage up to 6 suit storages, so this configuration leaves room for future expansion. Operators can adjust the installation based on their use case—adding or removing suit storages by replicating the gas supply and exhaust pipe connections without modifying the core architecture.

Exhaust Removal Formulas

The exhaust system uses a two-stage approach, similarly seen in Life Support I: Base Pressure and Composition: rapid internal evacuation to a buffer tank, followed by controlled external evacuation to the ECL (Exhaust Capture Line). This protects vulnerable walls and surfaces from burst events while maintaining efficient suit processing.

Buffer Volume Sizing

The suit storages’ inward lines connect to a minimum 640 L volume to ensure that gases are safely evacuated regardless of bottlenecks in the ECL pipe network:

Where:

Vbuffer = buffer volume (L)

Vcanister = canister volume (64 L)

Pcanister_max = maximum canister pressure (20,265 kPa for smart canisters)

Pmax = 50,662.5 kPa (90% structural limit - operational high watermark)

Psafety = 48,636 kPa (80% structural limit - pump activation threshold)

Pump Rate Calculation

When buffer pressure exceeds the safety threshold, volume pumps with a 25.6 L/tick capacity activate to evacuate the local inward pipe. Maximum pump rate:

The system preferentially uses passive drainage (directional valve) and activates pumps only when necessary to prevent overpressure in wall penetrations.

Components Required

1 Area Power Controller

1 IC Housing

1 IC10

3 Suit Storage

2 Pressure Regulator

3 Volume Pump

1 One-way Valve (Pipe Valve Kit)

1 Pipe Analyzer

2 Spray Paint (White, Black)

~6 Insulated Pipe Utility Gas

~40 Insulated Pipe

~20 Pipe

~50 Cable Coil

Color Coding System

Paint atmospheric infrastructure based on gas type:

Gray - Carbon Dioxide

Black - Nitrogen (propellant)

White - Oxygen (breathing)

Orange - Exhaust

Installation Steps

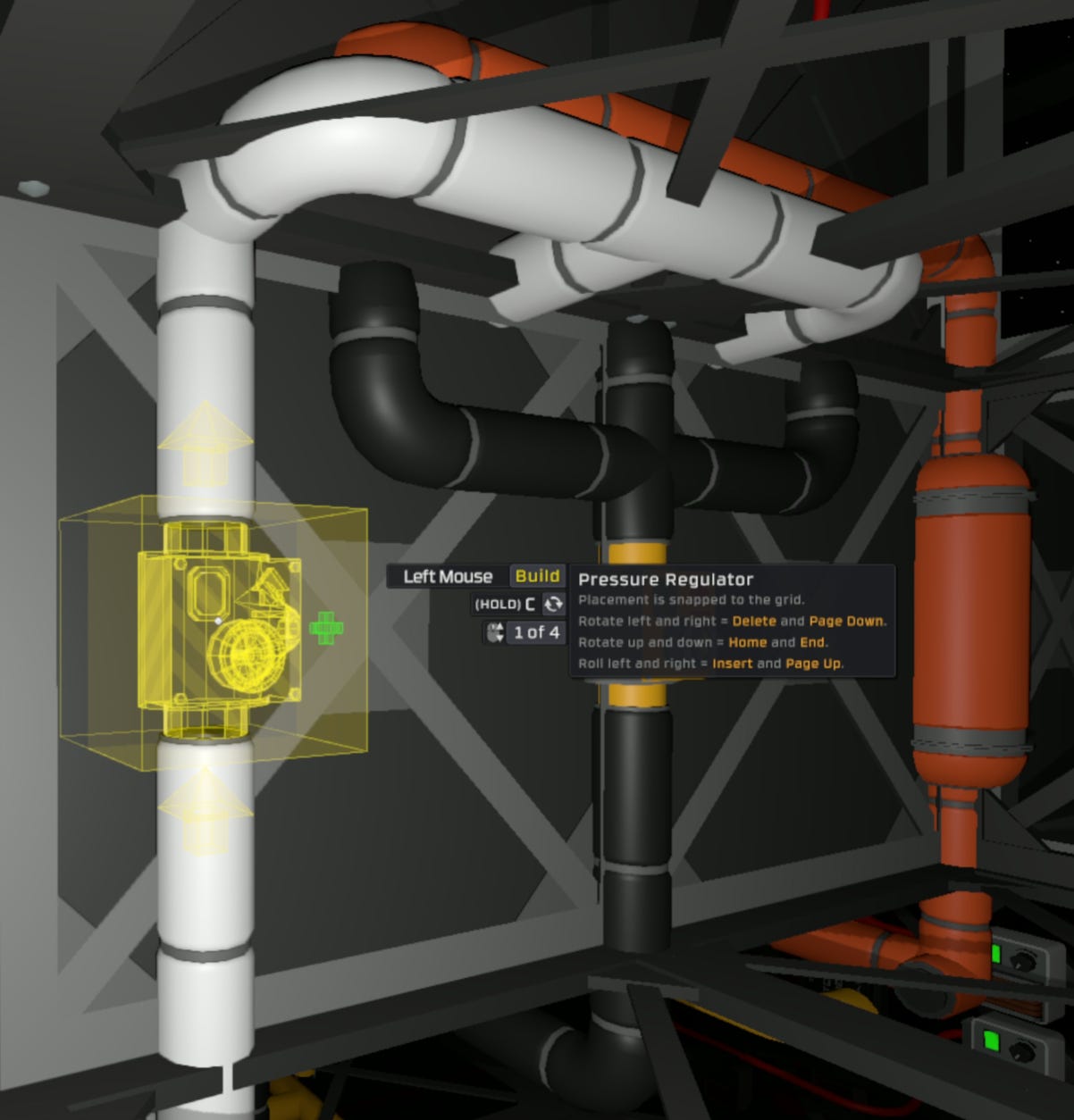

Install pipe connections for oxygen, nitrogen and exhaust on the exterior wall. Nitrogen is flush to the floor of the base. Exhaust is right above the nitrogen line, and oxygen is to the side of the nitrogen line.

Connect pressure regulators to the oxygen and nitrogen lines.

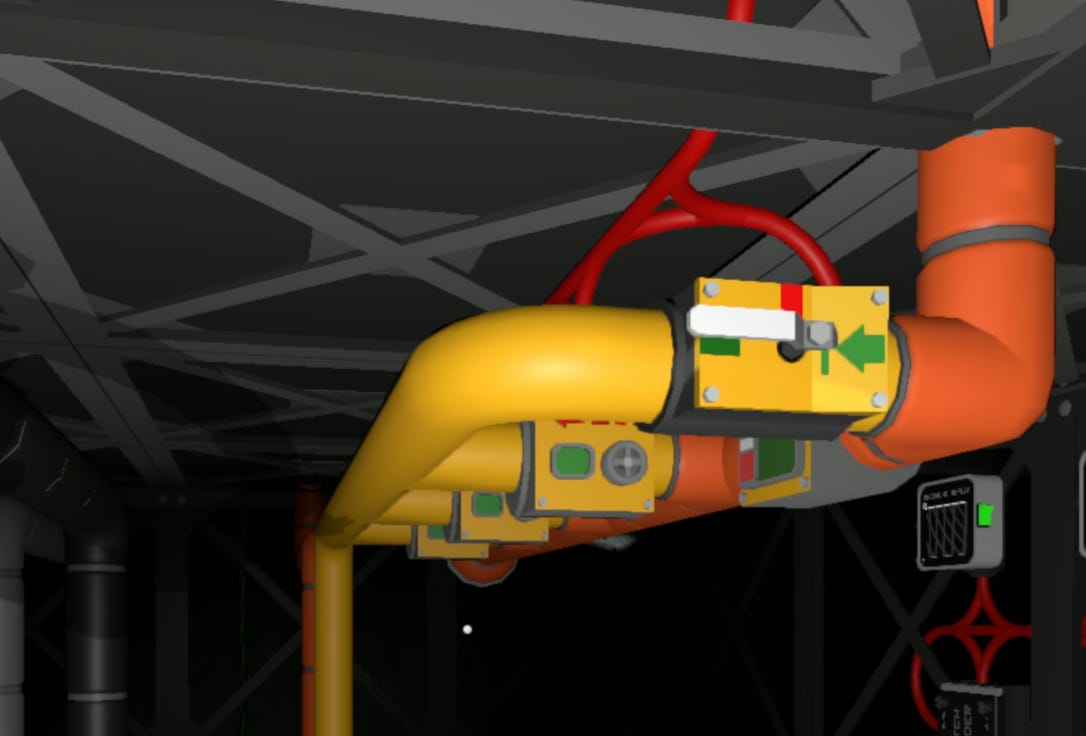

Connect and open the directional valve and attach pumps along the exhaust line to feed into the ECL.

Along the interior wall, install suit storages so that the nitrogen and exhaust pipes connect directly to the back of each unit. Snake the oxygen pipe so that it connects to the front port.

Cabling

Attach area power controller and IC housing and connect cables to

APC output

IC Housing (power and data)

Suit Storages (power and data)

Pressure Regulators

Volume Pumps

Pipe Analyzer

APC input will feed power from the PORTABLES transformer.

Configuration

Use the labeler to assign the following device names:

Pressure Regulators:

PortableOxygenPortableNitrogen

Exhaust Equipment:

Pipe analyzer, Volume Pumps:

PortableExhaust

Track 2: Canister Fill Station

This build provides infrastructure to support oxygen, nitrogen, carbon dioxide fills, and exhaust removal. The controller supports up to six configurable outward lines plus a dedicated exhaust line. All feed lines operate simultaneously, with fills automatically stopping at pre-defined pressure limits (hard-coded) based on canister type detection.

Fire-Safe Pressure Limits

Maximum fill pressures are calculated to ensure canisters remain below rupture thresholds even when heated to autoignition temperature (573.15 K) during fire scenarios:

Where:

Pburst = canister pressure rating (10,132.5 kPa standard, 20,265 kPa smart)

Tautoignition = 573.15 K (300°C - material autoignition temperature)

Tmin = 293.15 K (20°C - minimum expected line temperature)

Calculated Limits

Standard Canisters: 10,132.5 × 293.15 / 573.15 = 5,182 kPa

Smart Canisters: 20,265 × 293.15 / 573.15 = 10,364 kPa

These limits provide thermal safety margin, ensuring canisters can withstand fire exposure without rupture even during extended heating.

Components Required

1 Area Power Controller

1 IC Housing

1 IC10

4 Gas Tank Storage

3 Pressure Regulator

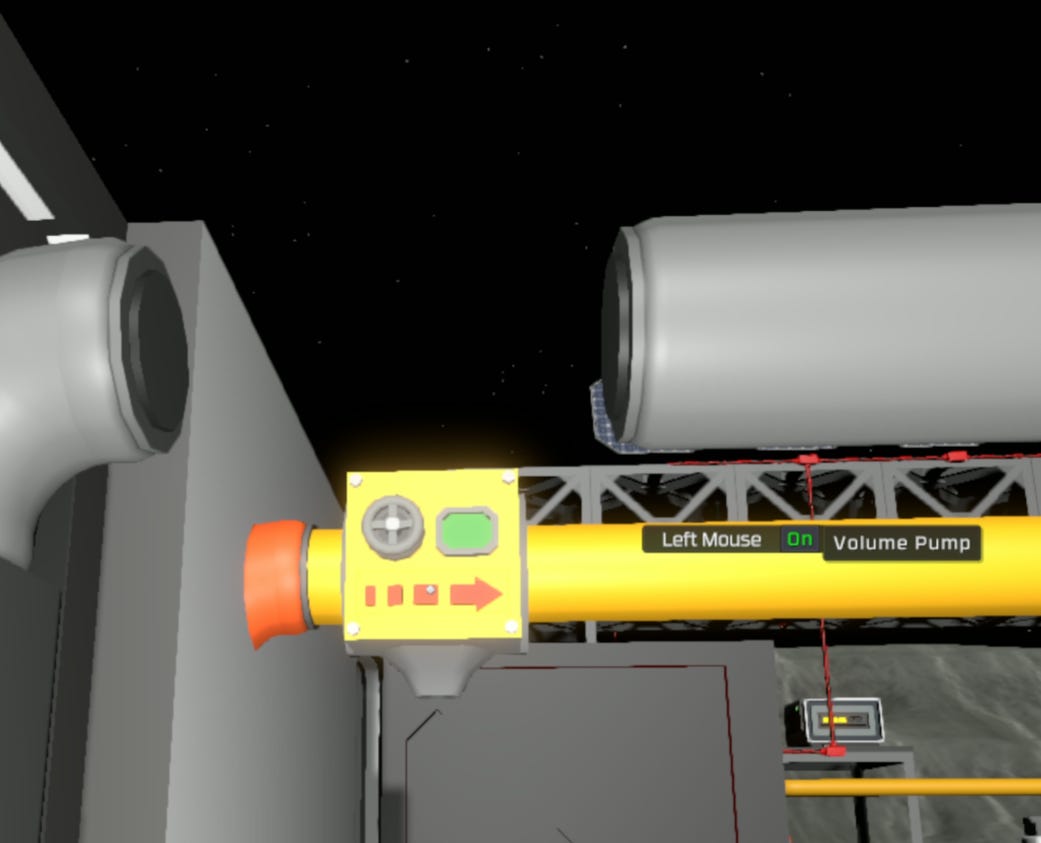

1 Volume Pump

3 Spray Paint (Gray, White, Black)

~60 Insulated Pipe

~20 Pipe

~50 Cable Coil

Installation

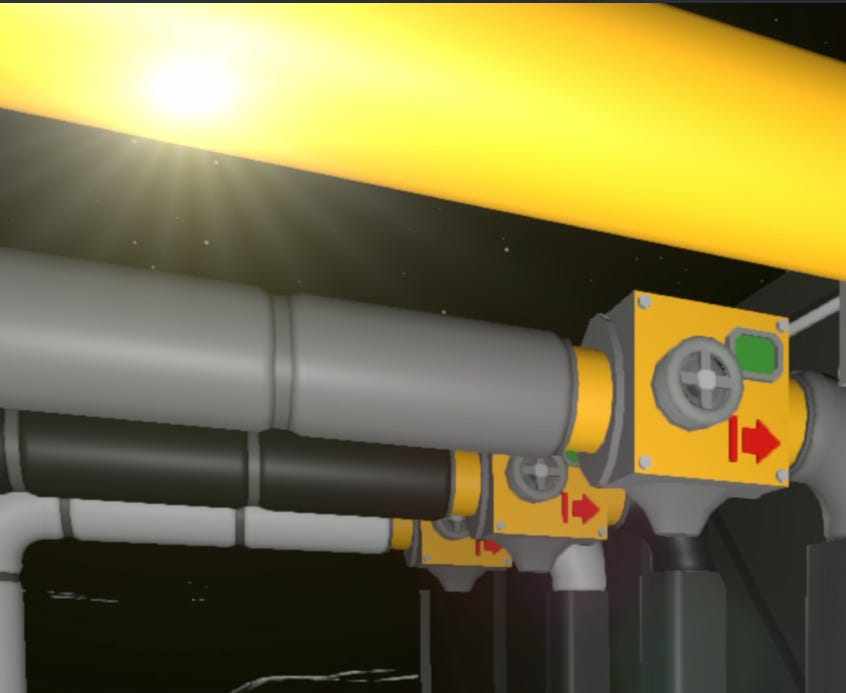

Attach Gas Tank Storages to wall surfaces, with each storage connected to a 10L pipe segment.

Connect pressure regulators to outward gas supply lines (O2, N2, CO2), oriented with flow direction pointing toward the Gas Tank Storages.

Connect a volume pump to the exhaust line, oriented with flow direction pointing away from storage toward the ECL.

Cabling

Attach area power controller and IC housing and connect cables to

APC output

IC Housing (power and data)

Gas Tank Storages

Pressure Regulators

Volume Pump

APC input will feed power from the PORTABLES transformer.

Configuration

Use the labeler to assign the following device names:

Outward lines (pressure regulator, gas tank storage):

PortableCarbonDioxidePortableNitrogenPortableOxygen

Note: When initially mapping gas tank storages to controller, assign a temporary unique label (e.g. PortableOxygen_Temp) to distinguish it from the pressure regulator during configuration, then rename it to match the final label (PortableOxygen) once mapping is complete.

Exhaust Equipment (volume pump, gas tank storage):

PortableExhaust

Logic Initialization and Deployment

Port-Suit Controller

Monitors up to six connected Suit Storages and activates them when a suit is detected that is in need of a top off.

Functional Overview

Activates suit storage unit when connected suit requires battery charging, exhaust tank evacuation, and/or breathing and propellant top-off

Only activates one suit storage at a time to reduce instantaneous load spikes caused from charging batteries

Monitors exhaust pipe pressure to ensure safe levels and activates pumps as needed

Hardware Interface

d0..d5: Suit Storages

Configuration Parameters

- SafetyPressure (Safety Pipe Pressure kPa): 48636

- MaxChargeRatio (Maximum charge ratio to account for rounding error): 0.995

- LocalPropellant (label): "PortableNitrogen"

- LocalBreathing (label): "PortableOxygen"

- LocalExhaust (label): "PortableExhaust"Device Mapping

Outward gas lines (Propellant, Breathing):

Pressure Regulator: Controls outward pressurization of the connected canister. Recommended pressure setting: 5,182 kPa

Inward gas lines (Exhaust):

Pipe Analyzer: Monitors atmospheric conditions within the local exhaust pipe network

Volume Pump: Actively removes gases from the local exhaust pipe network

Port-Can Controller

Manages canister fill and evacuation operations across up to six configurable gas lines plus exhaust.

Functional Overview

Activates pressure regulator when canister is connected to a gas supply line

Activates evacuation volume pump when canister is connected to a gas exhaust line

Sets the target pressure based on the canister type (1x standard, 2x smart)

Hardware Interface

d0..d5: Gas Tank Storages

Hardware Labeling

Each Gas Tank Storage requires a matching pressure regulator with an identical label. The controller uses these paired labels to coordinate fill operations between the regulator (pressure control) and storage (canister connection).

Example:

Gas Tank Storage labeled

PortableOxygenPressure Regulator labeled

PortableOxygen

Configuration Parameters

- StandardPressure (Fill pressure for standard canisters kPa): 5182

- LocalExhaust (label): “PortableExhaust”Device Mapping

Inward gas lines (Exhaust):

Gas Tank Storage: Monitors canisters for gas supply to be evacuated

Volume Pump: Actively removes gases from the local exhaust pipe network

Deployment Checklist

Confirm the following before activating any logic-controlled systems. This ensures that the IC program is properly mapped.

Device Labels

Runtime-Required Labels

These labels must match exactly, as they are referenced directly in controller logic:

PortableExhaustPortableNitrogenPortableOxygenPortableCarbonDioxide

Convenience Labels (Recommended)

These device names are not used by logic programs, but make flashing and troubleshooting easier:

PortablesPORT-CANPORT-SUITSuitStorageASuitStorageBSuitStorageC

Power System Validation

Power on all network junctions

Excluding the controller, toggle on and off each connected device individually to ensure power connectivity

IC10 Chip Installation

Install the IC10 program into the logic-capable device. Update the device inputs on the IC Housing hardware to map to the devices that the controller should manage.

Final Hold

Do not turn on controller until full startup sequence has been completed and all systems are confirmed.

System Activation and Handoff

System components, logic devices, and power domains are now installed and configured. The system is structurally complete, and control logic is staged for deployment.

However, final logic activation must not proceed until all runtime behaviors have been individually validated and the Readiness Procedure is complete.

Final Preconditions for Runtime Handoff

The system must meet the following conditions before control can be handed off to automated logic:

All IC10 programs are loaded onto the connected computer

Logic files should be saved and flashed with the controller off, allowing for isolated verification of supporting systems.

Breathing and propellant pressure regulators are set to the desired pressurization setting

This is required only for PORT-SUIT regulators. For universal support across all canister types and fire safety, the recommended fill pressure is 5,182 kPa.

Gas tank storage and linked pressure regulator are labeled exactly the same

This ensures gas delivery to the respective line.

Proceed to: System Readiness Plan

Next Steps

With EVA portable infrastructure, the base now has reliable EVA suit servicing, flexible canister management systems, and patterns for delivering gases without permanent pipe integration.

This completes the foundational survival infrastructure collection which established base construction, basic power and water systems, atmospheric recovery and distribution, climate control, and portable resource management. These systems provide the minimum viable infrastructure for sustained habitation.

Safety and Monitoring Systems

The next collection focuses on operational safety through systematic monitoring and response infrastructure. The first module covers Monitoring and Alerting Systems—detecting hazardous conditions, issuing categorized alerts, and delivering notifications through multiple channels (tablets, beacons, PA systems, visual indicators). Proper alerting infrastructure enables early detection of failures before they escalate into emergencies.

Future Modules

Power Standardization — As electrical loads increase and diversify, power distribution requires systematic capacity planning and demand management strategies. Future modules will address load shaving techniques, multi-zone distribution architectures, and opportunistic high-performance networks that capitalize on solar storm energy surpluses for batch processing and energy-intensive operations.

Fuel Systems and Automated Smelting — As operations expand into resource processing and rocket fuel production, high temperature systems introduce fire risk and volatiles management challenges. Production systems will integrate fire suppression, thermal management, and disaster recovery procedures while covering furnace automation and fuel production workflows.

References

Reddit. Pressure Regulators Research https://www.reddit.com/r/Stationeers/comments/15ubzhq/research_pressure_regulators/

Stationeers Wiki. Suit Storage https://stationeers-wiki.com/Suit_Storage

Content developed in collaboration with Anthropic’s Claude, used for technical documentation structure, engineering analysis, and editorial refinement.

Love the closed-loop thinking here, especially how waste gas reintegration flows back into atmospheric recovery rather than getting dumped. The fire-safe pressure calc at 5182 kPa is smart risk management, basically planning for therml expansion before trouble starts. I've been biulding similar systems and that sequential suit processing to smooth out power spikes is something I shoudl've thought of earlier.