Power Capacity Planning

New construction requires energy, and proper power sizing is crucial for a successful space station. This guide describes how to plan these systems and estimate their usage.

Draft Version: 0.1.1

Introduction

The starter power equipment provided by the lander kit in Stationeers is barely sufficient for survival and inadequate for expansion. It supplies limited daytime power, forces devices to be shut off at night and restricts fabrication to daylight hours. Solid fuel generators offer extra power but require frequent mining and produce more energy than current systems can effectively store or distribute.

As the base grows, power demand quickly outpaces supply. Systems for food production, water recycling, and atmospheric control all require continuous energy—far beyond what the initial power setup can support. Workarounds like manually disabling devices or burning coal are unsustainable at scale.

To build a self-sufficient base, a deliberate redesign of the power system is required. This guide presents a methodical approach to sizing energy storage and generation capacity that would help enable stable operation of life support and manufacturing systems and lay the foundation for future expansion.

Key Concepts

Power vs. Energy

Power is the rate at which energy is used or generated. It is measured in watts (W), where

Example: A 100W device consumes 100 joules every second.

Power (W) determines whether cables, generators and transformers can handle instantaneous load.

Energy is the total amount consumed or produced over time. It is measured in joules (J), where

Example: Running a 100W device for 10 seconds uses

of energy.

Energy (J) determines how much storage is required to sustain operations over time.

Cable Sizing (Power Delivery Limits)

In sizing a power system, it is critical to ensure that wiring can handle peak power draw. Each cable type has a maximum safe load:

Standard Cable Max Power = 5,000 W

Heavy Cable Max Power = 100,000 W

Exceeding these limits will cause cables to fry and will require repairs.

Cycle Period and Capacity

While power is measured in watts, consumption could vary over time. Devices such as solar panels only generate during daylight, and others like the autolathe draw power variably depending on active use. Planning must consider total energy requirements over a complete cycle period.

Cycle Period: Duration between successive energy production windows (e.g. 20 minutes for one lunar day-night cycle).

When energy generation and demand are misaligned, energy storage must compensate. This is measured as cycle capacity ratio—the portion of the cycle during which energy storage is required. For example, on the Moon:

Solar panel active time: 10 minutes

Cycle period: 20 minutes

→ Cycle capacity ratio: 50% (storage needed for the 10-minute dark period)

Considerations

Before sizing any power system, it is important to define operational goals:

Systems should remain operable regardless of time of day.

Power levels should require minimal intervention (e.g., no frequent manual shutdowns or fuel replenishment).

Personnel must still be able to safely enter and exit the base even during a power failure.

Inventory

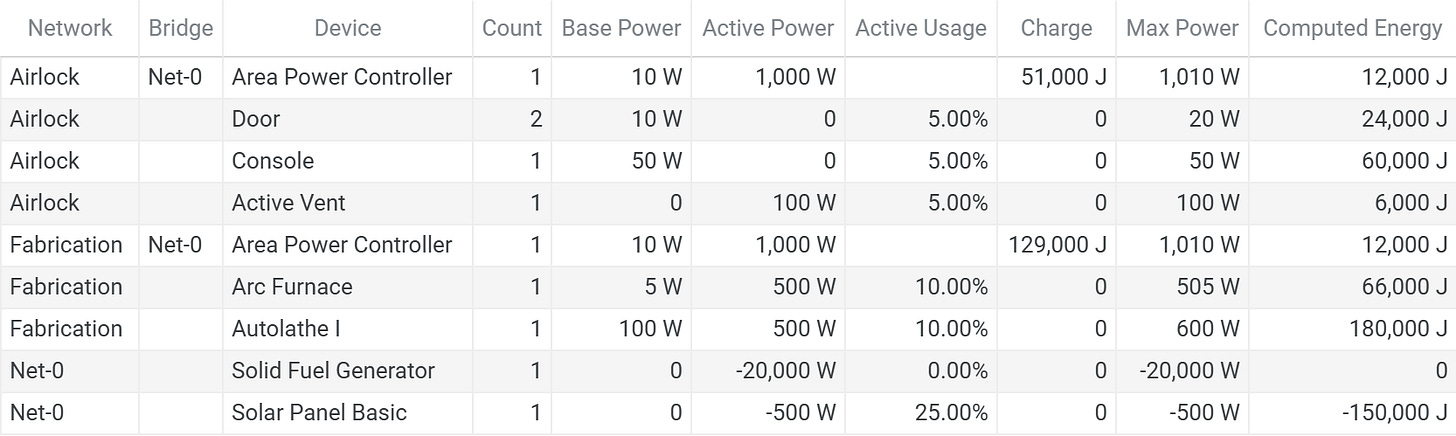

Gather a list of devices that will provide and consume power. Each device’s base power and active power characteristics should be noted. Below is an example based on a moon starter base using the standard landing kit:

Power Sources

Solar Panel Basic

Up to 500W, depending on solar angle

Solid Fuel Generator

Emits up to 20kW; requires solid fuel input (coal, charcoal, solid fuel)

Power Distribution

Area Power Controller

Base power: 10W

Up to 1000W when charging a battery

Additional load based on child network demand

Note: Area Power Controllers (APC) cap charge rates at 1000W, making them suitable for light-duty networks. In contrast, station batteries have no input wattage limit and are ideal for high-throughput charging.

Devices

Door: 10W

Console: 50W

Active Vent: 100W

Arc Furnace:

Base power: 5W

Up to +500W based on recipe

Autolathe I:

Base power: 100W

Up to +500W based on recipe

Networking

Devices should be organized into categories and assigned to networks that are separated by a network junction (station battery, APC, transformer)

A typical starter base includes:

Root Network (

net-0)Power generation and distribution point

Airlock Network

Isolated by an APC; powers doors, vents, and console for entry/exit

Fabricator Network

Supports manufacturing; powers devices like the autolathe and arc furnace.

Energy Usage

Estimate each device’s active usage ratio relative to the cycle period.

Example:

An active vent pressurizes and depressurizes the airlock for approximately 1 minute per cycle. If a solo Stationeer enters and exits once per lunar day (about once every 20 minutes), the active usage ratio is approximately 5%.

Key Calculations

Max Power Draw (Watts)

Where:

Pdevice = Max power draw (W)

n = Number of devices

Pbase = Base power (W)

Pactive = Active power (W)

Estimated Energy Usage (Joules)

Where:

Edevice = Energy used over cycle period (J) for a device

Uactive = Active usage fraction (e.g., 0.05 for 5%)

t = Cycle period (seconds)

Required Charge Capacity per Network

Where:

Cnetwork = Required charge capacity (J) for a network.

r = Cycle capacity ratio (e.g., 0.5 for 50% downtime)

Results

Using the outlined method, the following estimates apply to a typical starter base:

Total energy required: 360,000J

Max power draw: 3,295W (within the 5,000W limit for standard cables)

Network Storage Requirements

Airlock Network: 51,000J (satisfied by a large battery cell of 288,000J capacity)

Fabrication Network: 129,000J (also satisfied by a large battery)

Meeting Energy Demand: Production Solutions

The total energy requirement calculated in the previous section sets the baseline for system design. The objective is to select and configure energy production methods that fully satisfy this demand within the system’s cycle constraints.

Solar-Based Solution

A single basic solar panel, installed horizontally, generates approximately 150,000J of energy per lunar day. To meet the total system demand of 360,000J per cycle, the system requires at least three solar panels, assuming battery storage is sized to buffer energy during dark periods.

Solid Fuel Generator Solution

An alternative production method uses the solid fuel generator, which delivers higher output and can rapidly recharge station batteries. This is especially effective when paired with storage solutions that avoid the charging rate limitation imposed by APCs (1,000W max input).

The solid fuel generator can meet the total energy requirement with minimal runtime per cycle period, but would require a station battery and heavy cable to support the load:

Equivalent to 4 coal burned per cycle period.

Solution Selection

Both the solar and solid fuel solutions are capable of meeting the energy demand. The choice depends on operational goals:

Solar panels provide passive, fuel-free energy, that integrate easily into the existing system, but they require additional real-estate to support the needed capacity.

Solid fuel generators provide rapid, on-demand energy delivery, but require upgrading power delivery and capacity storage infrastructure. They consume finite resources that require active refueling or automation.

Alternatively, a hybrid configuration can combine both methods to balance sustainability, redundancy and performance.

Conclusion

Effective power capacity planning requires aligning generation, storage, and consumption through quantifiable metrics. By estimating energy usage over time and determining charge requirements per network segment, resilient systems that maintain continuous operations are possible.

Content structure and technical calculations were enhanced with support from AI tools (ChatGPT).